Architect Jonathan Davis will speak at Dwell on Design – Friday June 21

Prefab Goes Big, Onstage Preview with Jonathan Davis

Prefab is one of our favorite subjects at Dwell on Design, and this year we’re picking up the discussion with a variety of prefab panel discussions. One of them, Prefab Goes Big will feature architect Jonathan Davis of pieceHomes and the exciting new large-scale prefab development Grow, on Bainbridge Island in Washington. Here’s a preview of what we’ll discuss onstage on Friday, June 21st.

Prefab is one of our favorite subjects at Dwell on Design, and this year we’re picking up the discussion with a variety of prefab panel discussions. One of them, Prefab Goes Big will feature architect Jonathan Davis of pieceHomes and the exciting new large-scale prefab development Grow, on Bainbridge Island in Washington. Here’s a preview of what we’ll discuss onstage on Friday, June 21st.

For our session we’re talking about prefab at all scales. Your project, Grow on Bainbridge Island, could be very large indeed. Why prefabricate the houses that are a part of Grow?

Prefabrication, in this case panelization, allows for a more efficient construction process, thereby saving time and money.

How many are built now and how many are on the boards?

Three homes have been completed at Grow Community. There are three homes currently being framed, four with completed foundations, and four have foundations being built. The first three-acre phase will have a total of 24 single family homes and 20 apartment units in two buildings. Construction on these will be completed late this year. There is a five-acre second phase that will have 26 more single family homes and an additional 61 multi-family units.

You’ve got a variety of types of homes at Grow. Can you tell me how they differ from each other? The benefits of each model?

There are actually four different models of homes plus the rowhouse apartment buildings. All of these homes are also available from pieceHomes as modular homes. The single-family homes range from 1,100sf to 1,850sf. They include: the Tallis, has which has two bedrooms and one or two baths. This is available as both a freestanding home and a duplex. The Aria, at 1,540 sf, has two bedrooms, two baths, a mudroom and a large open flexible living space. The Ocean, is our multi-generational home that offers two master suites, one on the ground floor and one upstairs, with a large roof top deck off it. The Everett, is the family house with three bedrooms, two-and-a-half baths, a mudroom off the entry and an office/play area and study. The rowhouse apartment building, also designed to be built modularly, has 450sf studio apartments, 900-square-foot two-bedroom flats and 1,050-square-foot two-story, two-bedroom town homes. This will also available from pieceHomes later this year.

Is there a scale of development at which prefab wouldn’t work? Or can you just keep making them?

In my mind the larger the development project the more suited it becomes for prefab; as repeatability of the same design is really where you see savings in the cost of construction. For example, a factory can be more efficient if it can produce 10 of the same home, whether you are building modular or panelized.

——————————————————————

Prefab Goes Big Session Details

Though you’d be forgiven for thinking that prefab design is little more than whatever factory-made box can fit on the back of a flatbed, poky little prefab homes tell only half the story. Thanks to hybridized construction, the endless possibilities of modular building, and an ever-mounting appetite for efficient housing, we’re seeing more and more square footage with a prefabbed roof over its head. In this session we’ll talk with architects Leo Marmol, Whitney Sander, and Jonathan Davis—who will also share images of their recent projects—about how prefab housing is scaling up.

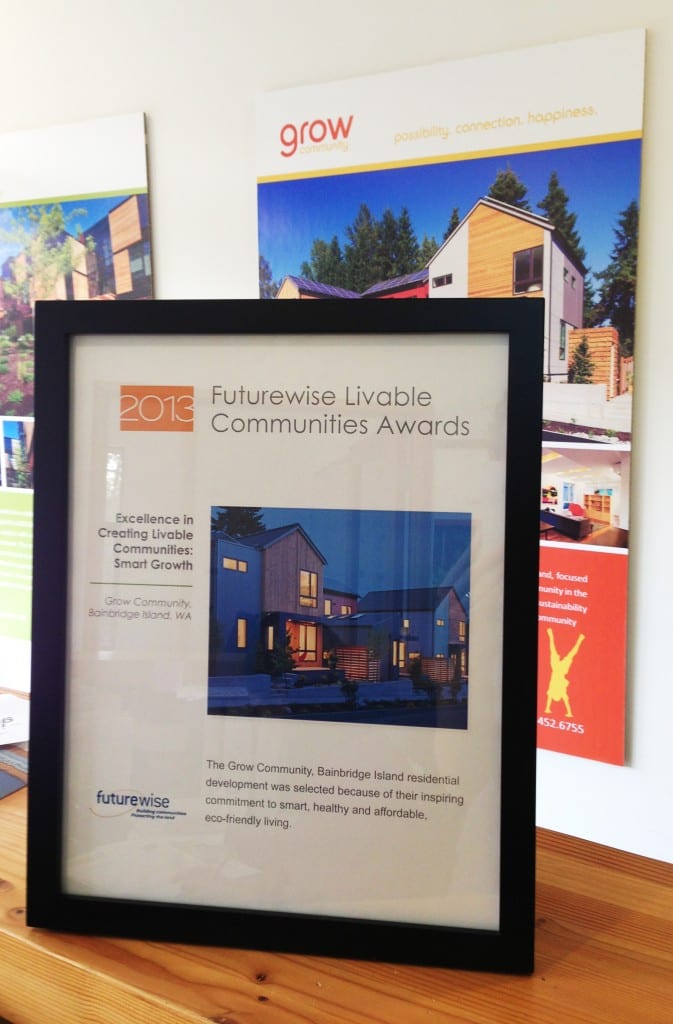

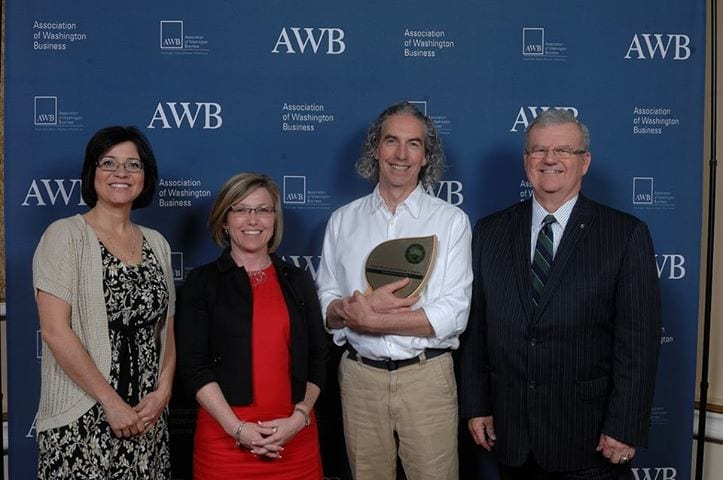

Grow Community Architect, Jonathan Davis of Davis Studio Architecture + Design received the 2013 AWB Environmental Excellence Award for Environmental Innovation from the Association of Washington Business for his work on Grow Community.

Grow Community Architect, Jonathan Davis of Davis Studio Architecture + Design received the 2013 AWB Environmental Excellence Award for Environmental Innovation from the Association of Washington Business for his work on Grow Community.

We are very excited to announce that Grow Community homes have achieved 5-Star Built Green status, the highest rating for Built Green certification.

We are very excited to announce that Grow Community homes have achieved 5-Star Built Green status, the highest rating for Built Green certification.